India's #1 Semi Automatic Pipe Bending Machine Manufacturer & Supplier

Bendtech Engineers manufacture and supply range of high quality Semi Automatic Pipe / Tube / Bar Bending Machine with Hydraulic Clamping

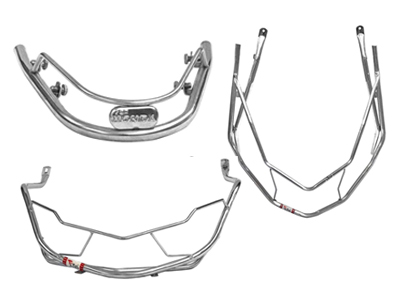

Bendtech Engineers tailors the need of a client according to the usage of the machine. The machines are available in variants as in heavy duty and light duty. Mechanically operated, Semi-Automatic pipe bending machine is used for multiple purposes like two-wheeler accessories, decorative accessories, automotive seat frames. These Bending machines are user friendly for mass production.

| Categories | Semi Automatic Pipe Bending Machines |

|---|---|

| Brand | BendTech Engineers (Brand Name:- BTE) |

| Model | BTE-SAPBM |

| Condition | New |

| Raw Material | Round Pipe, Square Pipe, Rectangle Pipe |

| Material / Metal Processed | carbon steel, stainless steel, copper, aluminium, galvanized, etc. |

| Power | Electrical |

| Automation | SEMI AUTOMATIC |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Operation | By Remote Box (LED Display) |

| FOB port | Mundra Port(Gujarat) , Nahva sheva Port(Maharastra) |

Applications

- Furniture

- Hydraulic piping

- Decorative items

- Automotive Seat Frames

- Two wheeler accessories

| Semi Automatic Pipe Bending Machine | ||||||

| Sr No. | Details | Specification | Specification | Specification | ||

| 1 | Model No. | BTE-2SAPBM | BTE-3SAPBM | BTE-4SAPBM | ||

| 2. | Pipe Size Max | 50 mm | 75 mm | 100 mm | ||

| 3. | Pipe Size Min | 10 mm | 10 mm | 10 mm | ||

| 4. | Pipe Wall Thickness | Up to 3.5 mm | Up to 3.5 mm | Up to 4 mm | ||

| 5. | Pipe Material | S.S., M.S | S.S., M.S | S.S., M.S | ||

| 6. | Bending Direction | Clockwise | Clockwise | Clockwise | ||

| 7. | Max. Bending Radius | 200 mm | 200 mm | 200 mm | ||

| 8. | Mini Bending Radius | 1.5 D | 1.5 D | 1.5 D | ||

| 9. | Max Bending Angle | 1800 | 1800 | 1800 | ||

| 10. | Bending Accuracy | ±1.5 % | ±1.5 % | ±1.5 % | ||

| 11. | Bending Speed | 180/14 sec | 180/14 sec | 180/14 sec | ||

| 12. | Mandrill Length | 2500mm | 2500mm | 2500mm | ||

| 13. | Max Hydraulic Pressure | 150 bar | 150 bar | 150 bar | ||

| 14. | Operating Voltage | 415v, 50Hz,3ph | 415v, 50Hz,3ph | 415v, 50Hz,3ph | ||

| 15. | Motor Power | 5Hp | 7.5Hp | 10 Hp | ||

| 16. | Hydraulic Valves | Yuken | Yuken | Yuken | ||

| 17. | Motor | Crompton Greaves | Crompton Greaves | Crompton Greaves | ||

| 18. | Pipe Clamping and Dis-clamping system | Automatic | Automatic | Automatic | ||

| 19. | Electronic Parts | L &T , Schneider | L &T , Schneider | L &T , Schneider | ||

| 20. | Control Panel with PLC | 7 inch color LED Display | 7 inch color LED Display | 7 inch color LED Display | ||

| 21. | More than 6 angle in single Program | Yes | Yes | Yes | ||

| 22. | One Die Set with Mandrel | BTE | BTE | BTE | ||

Playlist

2 Videos